CATEGORIES

Electro-Optical Characterization

Testing what the Laser should Actually do

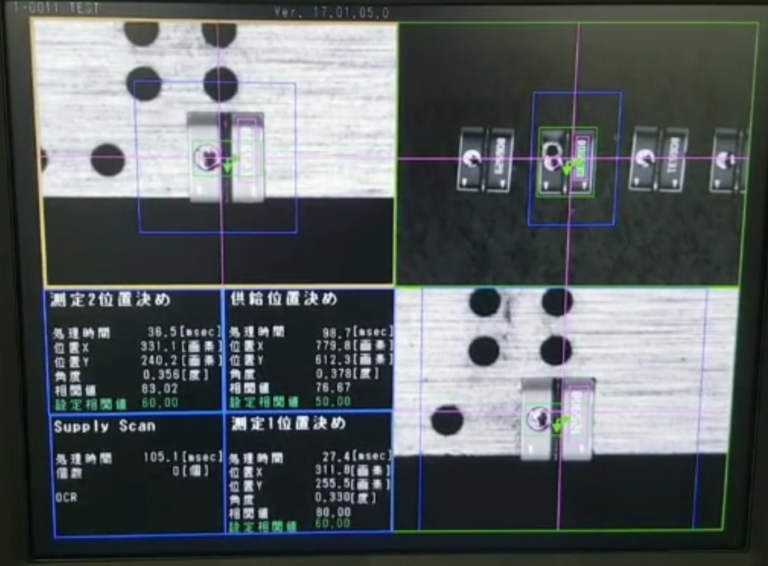

In this wiki we cover the laser diode characterization technology for large batches of laser diode production. In principle this applies to R+D individual measurement too. The main difference might be that there is always an implicit effort to simplify and reduce the effort on the one side and maximize the informative value of the extracted measurements on the other side. The cost pressure on the laser diode production leads to very ingenious ways to get a quick picture of the electro-optical characteristics of the laser diodes without spending more time doing it than absolutely necessary. The laser diode characterization is not only important to improve new designs, but also to make sure that the key specifications of the laser diodes are met and deviation trends are quickly detected.

The measurement SetUP

Damage and degradation mechanisms are depicted at another wiki chapter, but so much be said: Testing equipment will require special attention to the power source and the ESD protection of the devices. The bare laser diodes chips are very sensitive to electric damage (both current spikes and reverse current) arising from inadequate power sources or from ESD. Thank to their low inherent impedance they are prone to quickly react to current changes. The improper choice of voltage-controlled power sources are a surprisingly frequent cause of laser damage. Power sources for laser diode operation must always be current controlled instead and carefully designed not to produce any current spikes over the specified current limit. ESD protection is another topic of paramount importance that must be accounted for at every step of the laser diode handling.

During the manufacturing of the laser diodes, this is likely the first time that laser radiation risks need to be taken care of. The testing equipment for laser diodes must be shielded accordingly, not allowing stray laser radiation to exit the machine and pose a health risk. For this purpose also interlocks must turn off the laser power source if the doors or encasement of the testing equipment open. OptoSystem’s testing equipment fulfills laser class 1. Otherwise further shielding and warning lamps, in-depth operator risk assessing training and other measures might be necessary.

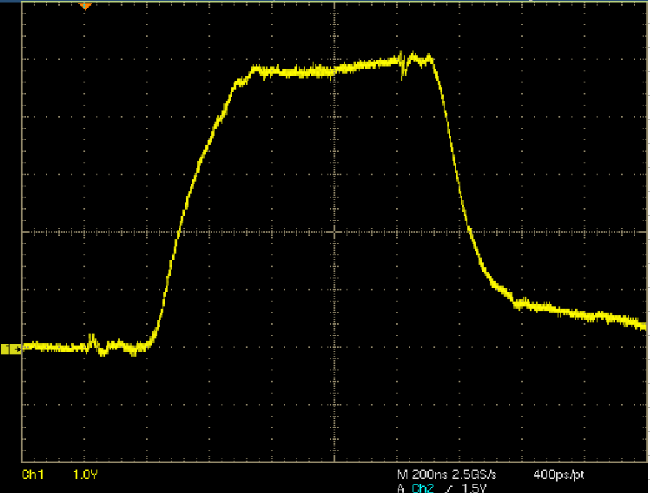

30A current pulse with 1µs length. It can prove difficult to provide the full amount of electric current without overshooting. Even short peaks can destroy the laser diode.

Do you like what you see?

We value your feedback, so let us know what you think!

Let us also know which topics you would like to see expanded.

Just give us a call, send us an e-mail or use the form to contact us.