Solid Functionality in Stacking

Description of the Manual Laser Bar Stacker Unstacker Station

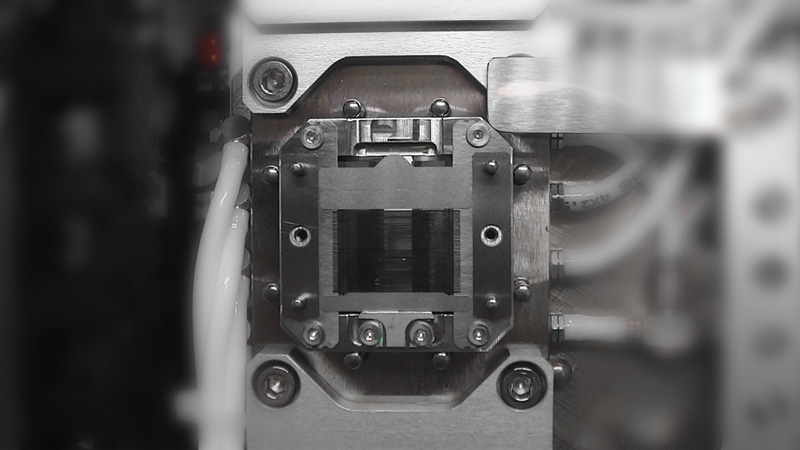

This tool represents the core techology of each Stacker and Unstacker from Opto System. With this tool and the corresponding jigs (holders for laser bars) you can manually stack and unstack laser bars of virtually every size and resonator length. The tool has been designed to hold the laser bars in place without damaging the delicate facets. It does lack indeed the speed and productivity of a full automatic system, yet the initial cost is much lower. As an additional benefit, if you decide to upgrade to a full automatic system later on, you can use the same jigs and spacers, which are a significant part of the investment.