CATEGORIES

Batch Break Mode

Chip Dicing

The facets that are in the light path need to be flat and perfect like a mirror. The cleaving for this primary cut has to be done meticulously one bar at a time to achieve the required level of quality.

If your end product is not a bar, you will still need to break the bars into chips after the facet coating. Although the requirements are less demanding, however it is usually very time consuming because we are moving further away from the wafer into single chips. A lot of dicing needs to be done!

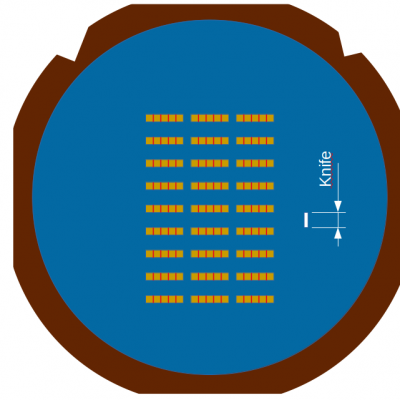

In a previous wiki we explained how a small knife can help you to place many bars on one frame. Since this is done automatically thanks to the vision system of the breaker, you don’t have to spend time manually aligning bars. Although this function is covered by the machine, it just takes time.

In this schematic depiction, a large number of bars are placed on one frame. The breaker will automatically dice all the positions.

Batch Break Mode

The next step after the facet coating is to unstack the bars from the coating jig. If you do this manually, the bars can be broken into chips using the method described above.

But if you have an unstacking tool from Opto System, the bars can be placed with a very high accuracy placement with deviations below 5µm.

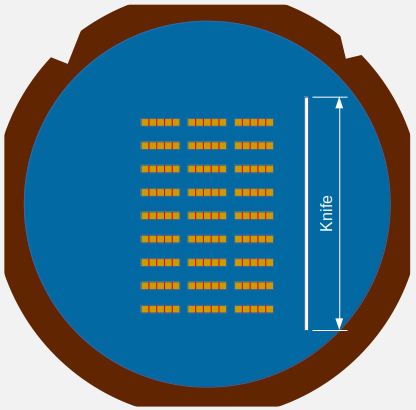

In this case, and only in this case, Opto System’s breaker can be used with a long knife and cut through all the bars with just one stroke. The breaker has a batch break mode that monitors the exact position of each bar and determines the best place to strike the knife against the support. This saves a lot of processing time and increases the production capacity of the breaker for chip dicing by a considerable amount!

In the batch mode, and using a long knife, Opto System breaker can dice many chips at once. But only if the arrangement of the bars is done within 5µm of maximum deviation. This is possible for Opto System’s unstacker tool. Link to the unstacker.

Do you like what you see?

We value your feedback, so let us know what you think!

Let us also know which topics you would like to see expanded.

Just give us a call, send us an e-mail or use the form to contact us.