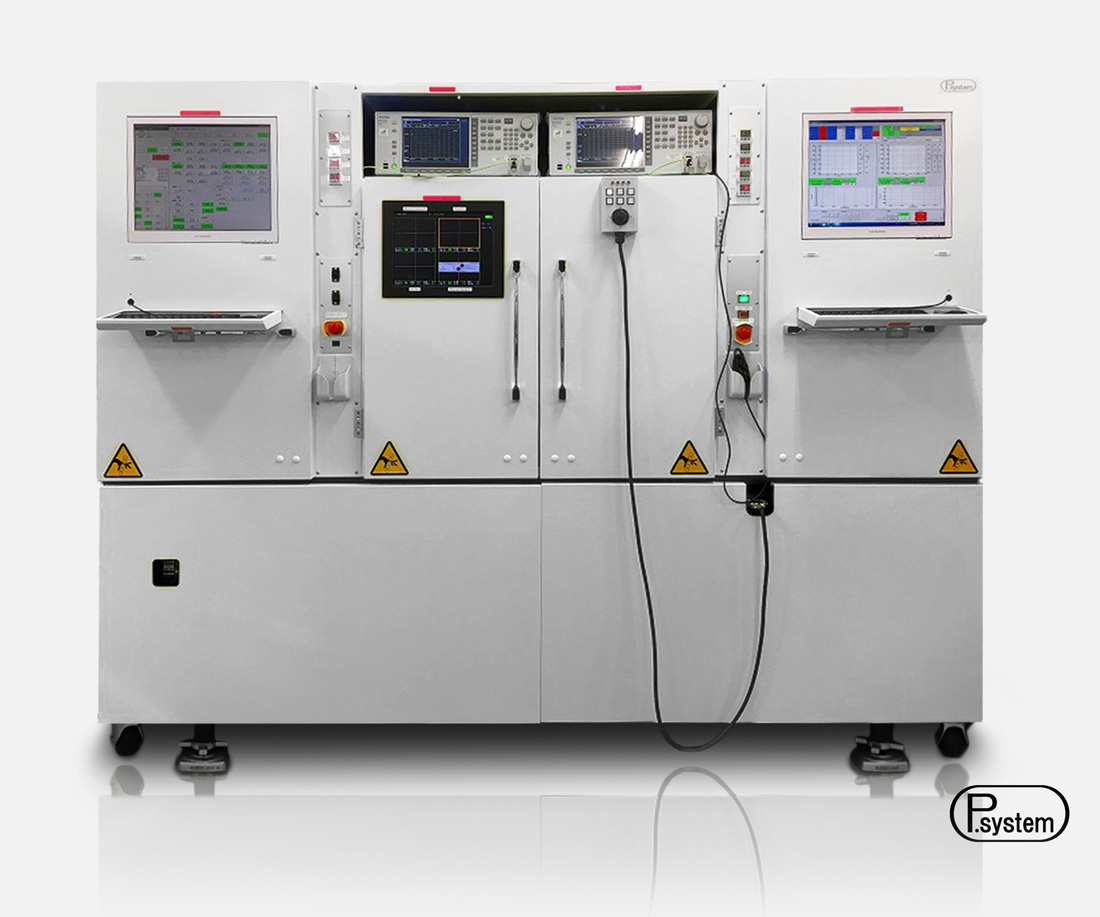

Full Automatic Measurement For Laser Chips At A Controlled Temperature

Description of the OptoSystem Laser Diode Chip Tester VMS3100

Knowing the behavior of your chips at the actual application temperature can be hard to achieve in a fast speed manufacturing environment. This full automatic tool from OptoSystem is a masterpiece in integration of machine vision, testing equipment and chip handling know-how. Although it is used for edge emitter laser diodes, it can be custom built for other types of semiconductor chips as well. The tool automatically picks up the chip from your tape, places it on the temperature-controlled chuck and performs a full electro-optical characterization before moving it forward to the sorting stage. The measurements include the integral light output power, the spectrum and the electrical properties. You may even set an electron-absorbtion-modulator (EAM) voltage as well for data communication laser types. According to the specified criteria, the laser chips are sorted in different GelPaks or Rings. This means you can offer your chips specified at the application temperature because you have tested it.