Discover Japanese Tools with us.

From the small series to high volume.

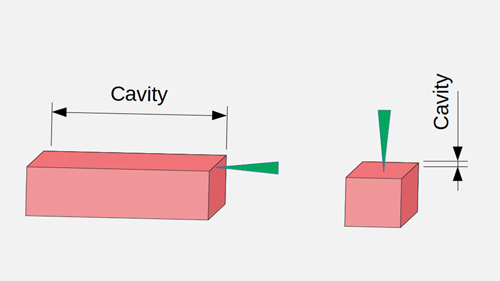

Scribe And Break

Such as diamond scribers, laser scribers and breakers from OPTO SYSTEM to singulate bars and dies from a wafer.

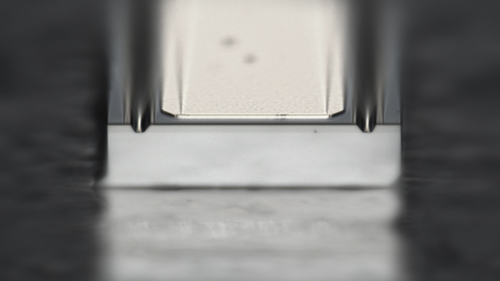

Bar Stacking

Stackers from OPTO SYSTEM pile up semiconductor bars to access bar facets for plasma treatment and coating.

Optical Inspection

Full automatic optical inspection tools from OPTO SYSTEM to sort out defects that can be identified visually.

Thin Film Coating and Plasma Etch

Electron resonance cyclotron plasma coating for laser diode mirror coating and other thin film coatings and etch processing tools.

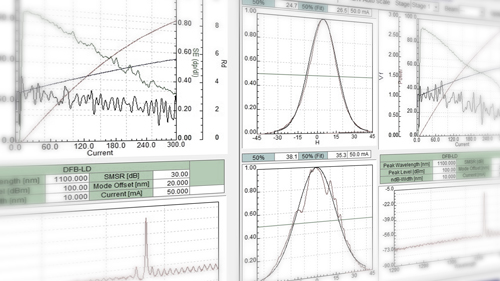

Testing And Probing

Full automatic high speed wafer probers, chip testers and bar testers from OPTO SYSTEM for full automatic characterization and sorting of opto-electronic and power devices.

Lithographie and Lift-Off

Customizable, low cost of ownership lithography solutions and lift-off technology from ASAP.