CATEGORIES

Managing Diversity: Having multiple Product Types without Chaos

When you purchase an automatic optical inspection tool from Opto System you not only get a plug and play system that works for your devices as intended. You also get the ability, after a short training that is part of the delivery, to modify and adjust the recipes and rules at your convenience. This is important as soon as you make modifications on your designs. You just need to load a recipe that has similar features, adjust the locations or sizes, save under a new name and you are ready to go. The whole process to adjust to a new type may take you half an hour or even much less.

Have a look

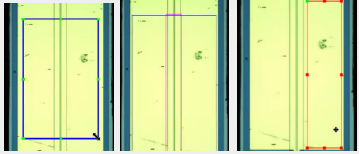

The process is very intuitive itself. You should just load the physical chip with the new design into the machine, load a recipe that already works and let it run on your new device. You will immediately see which are the fields that need to be adjusted. A typical adjustment will be to move the search region to its new location if the new device is asymmetrical, or reduce or enlarge its area. This is done with a game controller type of interface.

Starting out of an established recipe, it is easy to adjust the search region for a specific defect to a new device size or design. It is easy to add a mask (pink area in the middle) or move the search region altogether (right side)

Adjusting the judgement criteria

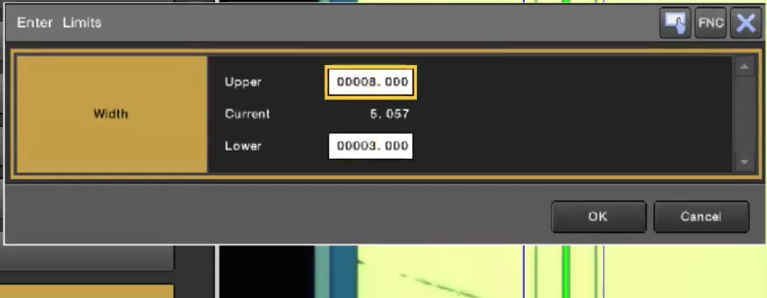

Obviously, if you are dealing with a new design, the sought-for size is now different. If your waveguide changes from 25µm to 5µm, you need to change these parameters so that the tool correctly judges the new size as OK, and a deviation of it as a reject.

Besides adjusting the location and size of the regions of interest, if an important measure has changed, you should enter the new low and high threshold for a rejection.

Same Design, Higher Requirements

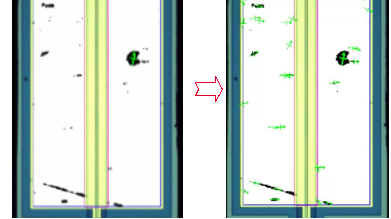

If the design itself has not changed, but you need to sort out devices with even smaller particles for a special requirement, it can be done within seconds: You just need to adjust the rejection threshold.

Same image left and right. The image recognition system, with this special filter does always find all particles but there is an important difference. In the left image, the threshold for rejection is “particles over 10µm” and the system only counts one. By reducing the detection threshold to 1 or 2µm, the counted particles rises to over 30 particles or defects. If your production is very clean, or your customer very demanding, you can enter a lower threshold.

Do you like what you see?

We value your feedback, so let us know what you think!

Let us also know which topics you would like to see expanded.

Just give us a call, send us an e-mail or use the form to contact us.