CATEGORIES

Applying AI on Automatic Inspection

We have introduced AI capabilities for certain situations where a very large number of chips with the same design can be used for training the AI computer. There is no need to do this for the rule based recipe method explained before. However, there are cases where comparing pixels would not give the expected answer.

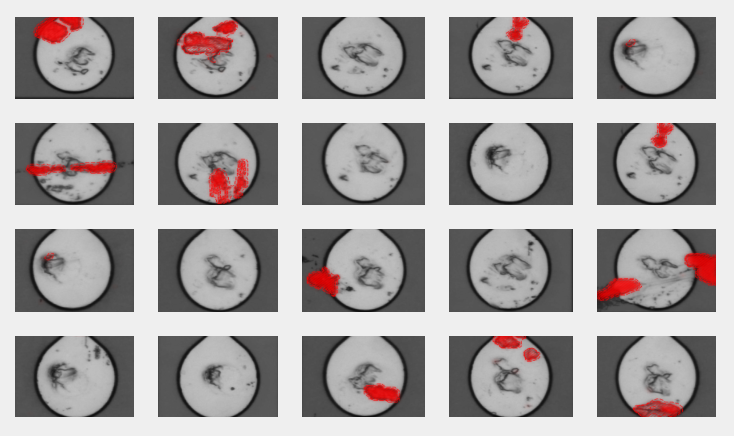

Prober Burn Mark

If the optical inspection is done after a prober measurement, very often we will face prober marks on the contact pads. Under many circumstances, it is possible to filter these images in such a way that the burn marks and particles or scratches can be distinguished. However, there are limits to this, and burn marks pose one of the more difficult challenges. With many chips, it is possible to train the AI system to be interlaced into the judgement

The prober burn marks on the device have a random appearance. However, with AI, it is possible to train the judgement to distinguish between harmless marks and real damage or defects. Image courtesy from UPVfab (link). This image has been digitally modified for the sake of illustration.

Requires more Samples and more Work

We do start out from easy-to-understand inspection rules. The reason is that a whole program can be set-up just from one sample and verified with relatively small amount of samples. Also, the behavior and outcome is foreseeable. With AI, very difficult inspection items can be improved in accuracy, but there is need for a more thorough training with many more samples. If you have a large volume production of a limited amount of designs, this approach can be done without impacting your engineering force by a lot. For customers with low-mix high-volume this approach can help decrease their false negatives and reduce workload in the long run, despite having a more elaborate set-up.

Training AI for distinguishing prober marks from other defects can be very rewarding. However it does improve the accuracy with the number of sample images. It means that the set-up work is more elaborate and requires more physical samples than a rule based set-up.

tell us what you actually want

We are very open to working with you on virtually any tool design topic. If you have your own logarithm for automatic optical inspection, let’s talk about it. Opto System is able to integrate a different inspection “brain” into a sorting tool, to adapt their current system to your demands, or to just deliver a plug and play tool to you with their expertise.

There is a specific standard-ish tools that you can find on our webpage. However, the specialty of Opto System is to manufacture a one-tool that suits your requirements perfectly.

Do you like what you see?

We value your feedback, so let us know what you think!

Let us also know which topics you would like to see expanded.

Just give us a call, send us an e-mail or use the form to contact us.