High Coating Uniformity.

Low Resist Consumption.

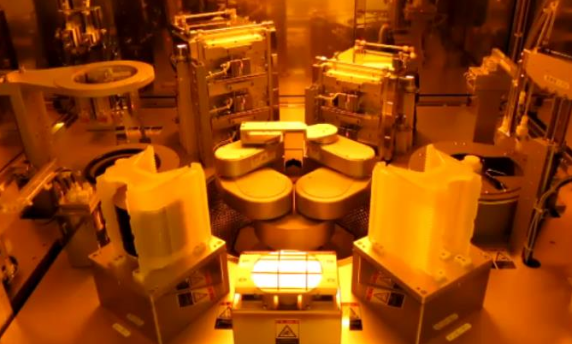

Description of the ASAP Coater Tool and its Highlights

Good pattern resolution depends of a homogeneously coated wafer. Yet, this can be sometimes demanding. ASAP has been building spin coaters for over two decades: For small labs and for large fabs. Especially, if you are dealing with non-Si wafers, or your process size is comparatively small (up to 8 inches) you might find it challenging to find affordable tools with top-notch processing quality. ASAP is the perfect supplier for you. Focusing on high quality components and a lot of little but fine details have led to awesome tools that you will love for their ease of operation, low cost of ownership and reliability. We listen to your specific situation and requirements. Please do reach out today.