High Yield; Low Cost Of Ownership.

Description of the ASAP Lift-Off Tool and its Highlights

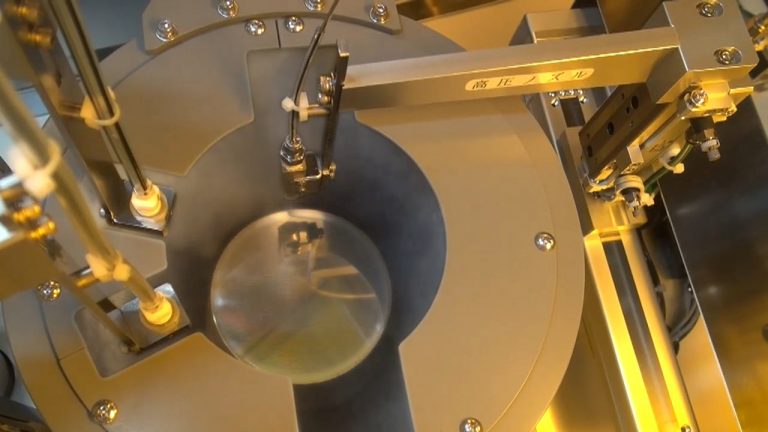

Lift-Off is a relatively cheap structuring alternative when etching might have a negative effect on the underlying layers. However, lift-off can be a messy process. The main problems are re-deposition of the lifted metal, retention of unwanted parts of the metal layer and non-removal of the metal ‘ears’. The lift-off tools from ASAP address these issues in elegant and efficient way with a number of technological details. As an example, the unique high-pressure nozzle adds mechanical strength to the chemical function of the solvent and achieves a very high yield even in challenging constellations.